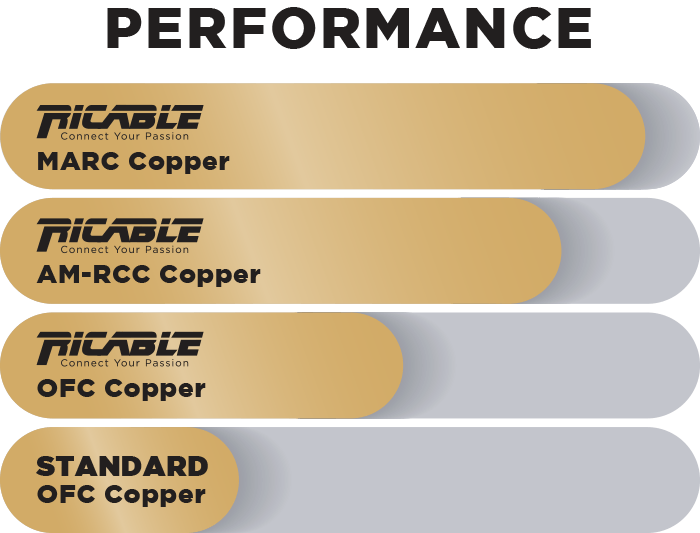

In 2015 we introduced AM-RCC conductors into our Power cables, and the result was outstanding. Since then we have been working on further improvement of our conductors, because although the result was already very good, we saw room for significant improvement.

These studies led to the creation of the new MARC© conductor, which stands for Multicore Annealed Ricable Conductor, and which is used throughout Magnus, Dedalus and Invictus.

The improvements made made it possible to produce a copper conductor with 7N (99.99999%) purity that is more malleable than its predecessor, due to the reduction of grains per meter by 25% compared to AM-RCC. This production implementation allowed strands to be produced that was smoother on the surface, more ductile and smaller in diameter.

The advantages are as follows:

1.Greater quantity ofraw material:

The conductor wires are thinner and in greater quantity, for the same cross-sectional area, and consequently, with the same conductor surface, we have a greater quantity of copper

2. Skin effect reduction :

By increasing the number of wires in the conductor and reducing the grains of processed copper with consequent surface compaction, a substantial reduction in the skin effect is achieved, which in audio applications is one of the major causes of acoustic signal degradation.

3. Lowering Resistance:

Another effect of the increased decrease in wire diameter, with the resulting increase in the amount of copper, the electrical resistance has also been reduced considerably.

4. Flexibility:

MARC© Copper, in addition to its acoustic and electrical benefits, has improved cable flexibility by up to 70% compared to OFC Copper.

5. Acoustics:

The new MARC© processing, together with the other innovations introduced, produces in the sound a greater transparency, a better detail, a more characterful Soundstage, all while maintaining the neutrality that has always distinguished our production.